Natural wear is a completely normal and normal physical process. What are its reasons? What about the measurement methodology? What species diversity of this process emit? These and other questions will be answered in the framework of this article.

general information

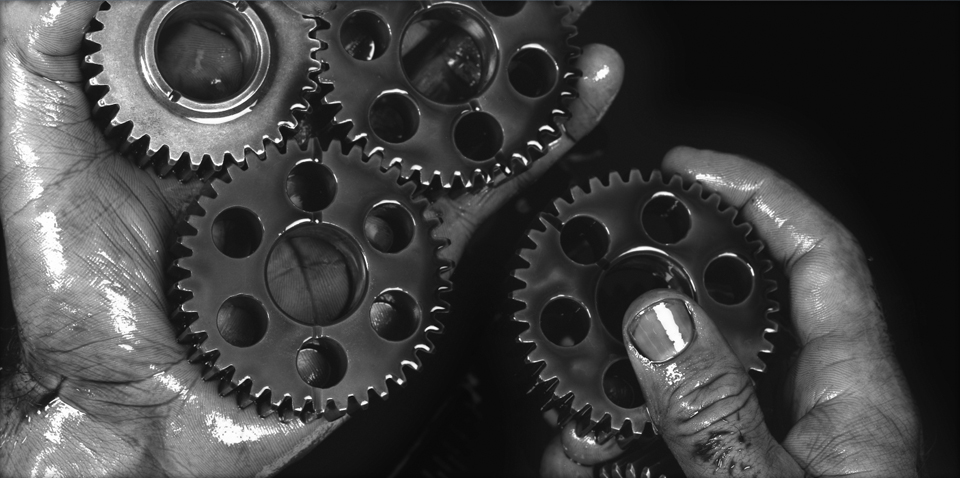

Begin with a definition. Natural (physical) wear is a natural process of deterioration of the characteristics of an object during its use. It occurs under the influence of a number of factors, such as: corrosion, vibration, friction, aging of materials, quality of service, deviation from recommended operating values for humidity and temperature. Growth leads to an increase in the likelihood that an equipment failure will occur, the quality characteristics of products manufactured with it will decrease, the residual life of some parts and assemblies, or even the entire product, will decrease, and the object will be declared unusable.

About types of wear

In practice, you have to distinguish between:

- Mechanical wear. Its result is a decrease in accuracy (deviation from cylindricity and parallelism).

- Abrasive wear. It suggests scoring and scratching on mating surfaces.

- Fatigue wear. It turns around the appearance of cracks and fracture of parts.

- Crushing - causes a deviation from flatness.

- Jamming - manifested in the adhesion of mating surfaces.

- Corrosion wear. It manifests itself in the oxidation of the wearing surface.

Separately, it is worth mentioning the causes of wear. Depending on them, changes of the first and second kind are distinguished. What does this mean in practice? Natural wear in the first case is a process whose potential has accumulated as a result of normal use. The second kind is used to characterize situations arising from accidents, natural disasters, violations of the rules of use, and so on.

About the time factor

Natural wear can also be considered from the point of view of its course. In this case, it can be continuous and emergency. Let's look at them in more detail:

- Continuous wear. This is the name for the gradual decrease in the technical and economic indicators of the object, provided that the correct and at the same time long-term operation is carried out. An example is the mechanical wear of parts and assemblies, which affects the moving parts of mechanisms and machines. It may affect other elements of the system.

- Emergency wear. This is what they call fast-time changes that reach such proportions that operation of an object becomes impossible in the future. An example is cable breakdown. By the nature of the course, it can be described as instantaneous.

It should be noted that emergency wear is almost always just a consequence of the occurrence of hidden processes.It may be externally related to personnel errors, mismatch between the required and available consumables, and sudden surges in the supply voltage. But the latent wear generated in this case does not directly affect the technical parameters. It simply increases the likelihood of an emergency.

Some more points of view on wear

Sometimes this process should be looked at from a different angle. Therefore, let's look at what other types of wear can be. The nature and extent of distribution distinguish:

- Global wear. This is the situation when the process is extended to the entire object as a whole.

- Local wear. This is the name of the process when various parts and components are affected to varying degrees.

Also, according to technical capabilities and economic feasibility of restoring lost consumer properties, there are:

- Disposable wear. This is a process that can be reversed physically and economically justified. That is, it allows for repairs and restoration of the facility.

- Fatal wear. In this case, it is impossible to reverse the process due to certain design features or difficult for economic reasons (for example, costs exceed the cost increase).

And more about the form of manifestation:

- Technical wear. This implies a decrease in the actual values of the parameters of the object relative to the normative (passport) data.

- Wear and tear. By it is meant the deterioration of the protective properties of the outer coating.

On the manifestations of wear

The obligatory side of this process is the increase in costs that are needed for the manufacture of products (in terms of the costs of materials, energy, etc.), maintenance, and repair. They significantly exceed the average level of costs for similar new facilities. Sometimes, when physical depreciation increases, costs do not increase. In this case, the costs will be below average. It may well be that a similar situation indicates an increase in hidden wear and delayed repairs. It’s hard to say exactly, since this moment depends on a number of factors, among which should be mentioned:

- Quality of care.

- Operating conditions - how much dust, whether humidity is increased, whether there are abrasive contaminants and the like.

- The degree of loading of the object, the intensity of use, the duration of the work.

- Features of the process and the degree of protection against the negative impact of the external environment.

- The quality of an object is the perfection of its design, the materials used, and so on.

- Qualification of personnel who are responsible for work and maintenance.

Each of these factors affects the service life and what will be the natural wear of parts, assemblies, equipment, structures.

Effects

Due to wear, the performance of equipment and machines decreases. This is due to downtime, repair, additional maintenance. In addition, there is a certain influence on the technical parameters. And only for the worse. For example, machining equipment degrades machining accuracy. Because of this, it is necessary to check and adjust devices more often. And you just do not need to forget about the simply increased output of defective products. For example, it is believed that in machines, efficiency can decrease over 10 years of operation by up to 25%.

How to influence the indicator?

Depreciation of structures, equipment, components and parts is inevitable. But stretching this process is quite possible. The actual value depends on the resource and the service life. The first parameter is determined by the operating time, while the second calendar duration of operation. Usually, when creating an object, it is indicated / calculated how much it can work. For example, a car is given a guarantee of 100 thousand kilometers or 5 years.But the environmental condition, the presence of peak loads, the frequency and quality of maintenance / repair, the mode and intensity of operation also have an additional effect. Keeping all these indicators within a reasonable framework, significant results can be achieved.

Conclusion

So it is considered what constitutes natural wear. Of course, this topic is very extensive, one article is clearly not enough to consider it in full. But the information read is enough to get at least a general idea. All that remains is to thank the reader for his attention and say goodbye.